Okay, enough with the boring stuff. Let’s look at how the interior design is shaping up.

Seating

The captain’s chair and passenger chair have been a very difficult decision because of the plethora of options. I love the marine style but I need the RV safety and comfort.  And then I found this unique seat, made by International Harvester — yep, for tractors. And tractor seats are notoriously comfortable. I couldn’t be happier with this find, especially given its styling. I’ll need to bolt on a lap belt, of course.

And then I found this unique seat, made by International Harvester — yep, for tractors. And tractor seats are notoriously comfortable. I couldn’t be happier with this find, especially given its styling. I’ll need to bolt on a lap belt, of course.

It will mount atop this adjustable, hydraulically-assisted Swivl-Eze pedestal. The steering wheel is inordinately tall, so it’s important for the captain’s chair to telescope up and down.

For the passenger chair, I’m leaning toward this Flexsteel model, which I’ve mocked up in Photoshop with a two-tone color scheme. Mine wouldn’t have the skirt and I’d mount it on the same type of pedestal. I haven’t ordered it yet, because it’s pretty spendy. It needs to recline and be more comfortable than the captain’s chair because I plan to work in it for hours at a time.

Cabinetry

I’ll be constructing all the bases, table and counter tops, shelves and a bulkhead out of 3/4″ maple plywood. I don’t want any wood tones to be visible in the design, so they’ll be painted. Hopefully something like a piano-grade lacquer finish.

Walls

The entire cargo area will be re-covered in 1/16″ thick aluminum panels. I count 19 panels total, and I’ll have them custom cut a local metal shop. They’ll be much easier to handle than the 12-foot sheets I had to remove. For access to cables, plumbing and fixtures I’ll mount them with screws instead of rivets.

The wall panels might be covered in this WilsonArt laminate, called Retro Diner. The samples I got just make me smile.

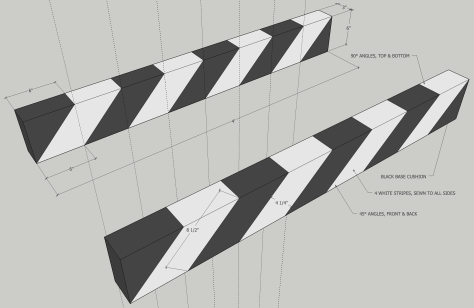

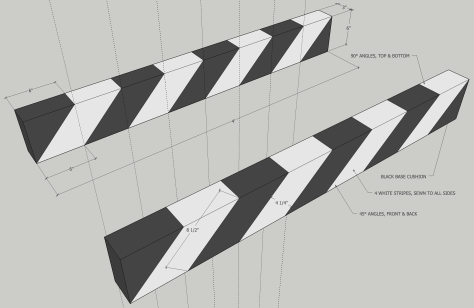

I’ll cover the custom dinette/berth in a future post, but these are important design elements that will mount on the aft walls as headrest cushions. I finally found a vendor (Tricia at cushionsource.com) who is willing to make these.

They represent a movie clapboard when a director calls “Action!” And they’ve been an integral part of my company’s branding since 1986.

This is an IKEA medicine cabinet that will mount on a wall somewhere.

This one will mount on the bulkhead above the captain’s chair. It’ll be be great for Zombie Apocalypse essentials like ibuprofen, sunscreen, bandages, antiseptic, toothpaste, ammo, etc.

Ceiling

The ceiling panels might be covered in these PVC ceiling tiles. The style is art deco, like you’d find in an old theater. These come in various metallic finishes but I like the contrast of white against the walls and everything else.

Lighting

There will be two banks of these six LED lights, one forward and one aft. Each light is small enough to nestle nicely in the center of an art deco ceiling tile.

And here are the LED dimmer switches, one per bank. The lights will be on the same 12V circuit, fed from the helm console. I love how big and fat they are. They come in black but the white is easier to find in the dark.

Ventilation

Two of these Fan-Tastic automatic vents will keep the interior cool and dry, hopefully obviating the need for air conditioning and reducing the chance of condensation and mildew. We’ll see…

Here’s the remote control for each vent/fan. The forward vent will be set to blow and the aft vent will be set to suck. That should help keep any engine smell out of the sleeping area.

Flooring

These interlocking 12-inch tiles are made from the same material as flip-flop shoes. And they’re durable and cheap enough to simply replace if they get damaged over time. Best of all, they’re cushy to walk on. They also have some sound-proofing and insulation properties. They’ll rest atop a plywood subfloor and maybe a foamboard insulation layer.

Galley This is the galley cabinet. It’s a 46×18-inch Husky mobile workstation (tool chest). I’m removing the wheels and the butcher block top, and will replace the top with 3/4-inch maple plywood fashioned into a 6-foot countertop with sink, retro formica and diner-style metal banding. The stainless steel handle might move to the left side and serve as a towel rack.

This is the galley cabinet. It’s a 46×18-inch Husky mobile workstation (tool chest). I’m removing the wheels and the butcher block top, and will replace the top with 3/4-inch maple plywood fashioned into a 6-foot countertop with sink, retro formica and diner-style metal banding. The stainless steel handle might move to the left side and serve as a towel rack. I’ve replaced the “HUSKY” emblem with a more appropriate one for the RETROvan, and it looks super geeky!

I’ve replaced the “HUSKY” emblem with a more appropriate one for the RETROvan, and it looks super geeky!

Here’s the sink. It’s 16×16 inches and 8 inches deep with a sound-proof coating underneath. This will mount above the cabinet door, surrounded by retro formica. I haven’t chosen a faucet yet but I’m considering using a wall-mounted one. That way I can route the plumbing through the 3-inch wall cavity instead of the cabinet, thereby saving space. I’ll address fresh water and gray water tanks later, but they can mount under the floor.

Here’s the WilsonArt Nostalgic Gray laminate for the countertop and table top. The boomerang pattern compliments the walls and reminds me of the Jetsons.

And here’s the retro aluminum tee banding, which I’ll install myself along the edges and rounded corners with a special slot cutter and a rubber mallet. To make the curves without deformation, the grippy tee flange must be cut out at strategic intervals.

Appliances The countertop will span over this cool retro refrigerator/freezer. The fridge will sit directly behind the driver’s seat, keeping precious cargo chilly for happy hour.

The countertop will span over this cool retro refrigerator/freezer. The fridge will sit directly behind the driver’s seat, keeping precious cargo chilly for happy hour.

Two ovens will stack above the fridge in the cabinetry. The convection toaster oven handles two 12-inch pizzas. This is not the exact microwave I wanted, but a bigger model with the oval window should be back in stock soon for an exchange.

Two ovens will stack above the fridge in the cabinetry. The convection toaster oven handles two 12-inch pizzas. This is not the exact microwave I wanted, but a bigger model with the oval window should be back in stock soon for an exchange.

A matching coffee maker will grace the countertop, with a matching waffle maker stowed away in the cabinet. Yep, it’s an awesome product line.

Miscellanous

Here’s the fun little retro JVC “Teeny Vision” TV and the iView digital media box I mentioned before. Great for home movies. This will probably complement an iMac or other flatscreen. Maybe even a projector.

This is just a nice welcome mat that happens to fit atop my front desk and glove box safe. Mazy, our cat, also likes it. 🙂

This is just a nice welcome mat that happens to fit atop my front desk and glove box safe. Mazy, our cat, also likes it. 🙂

The cockpit has an engine-fed heater to the left of the driver’s seat. But what RETROvan would be complete without an LED ceramic heater? This thing looks incredible and it will take the chill out of the night year-round, especially around the holidays.

The cockpit has an engine-fed heater to the left of the driver’s seat. But what RETROvan would be complete without an LED ceramic heater? This thing looks incredible and it will take the chill out of the night year-round, especially around the holidays.

And finally, this was a birthday present from my amazing wife. You can swap out the USS Enterprise schematic between Star Trek: The Original Series and Star Trek: The Next Generation. And the LED lights can cycle through eight colors. This will go somewhere near the helm console, which I’ll detail in a future post.

More to come…

This is the galley cabinet. It’s a 46×18-inch Husky mobile workstation (tool chest). I’m removing the wheels and the butcher block top, and will replace the top with 3/4-inch maple plywood fashioned into a 6-foot countertop with sink, retro formica and diner-style metal banding. The stainless steel handle might move to the left side and serve as a towel rack.

This is the galley cabinet. It’s a 46×18-inch Husky mobile workstation (tool chest). I’m removing the wheels and the butcher block top, and will replace the top with 3/4-inch maple plywood fashioned into a 6-foot countertop with sink, retro formica and diner-style metal banding. The stainless steel handle might move to the left side and serve as a towel rack.

The countertop will span over this cool retro refrigerator/freezer. The fridge will sit directly behind the driver’s seat, keeping precious cargo chilly for happy hour.

The countertop will span over this cool retro refrigerator/freezer. The fridge will sit directly behind the driver’s seat, keeping precious cargo chilly for happy hour.

Two ovens will stack above the fridge in the cabinetry. The convection toaster oven handles two 12-inch pizzas. This is not the exact microwave I wanted, but a bigger model with the oval window should be back in stock soon for an exchange.

Two ovens will stack above the fridge in the cabinetry. The convection toaster oven handles two 12-inch pizzas. This is not the exact microwave I wanted, but a bigger model with the oval window should be back in stock soon for an exchange.

This is just a nice welcome mat that happens to fit atop my front desk and glove box safe. Mazy, our cat, also likes it. 🙂

This is just a nice welcome mat that happens to fit atop my front desk and glove box safe. Mazy, our cat, also likes it. 🙂